Products

FEATURED PRODUCTS

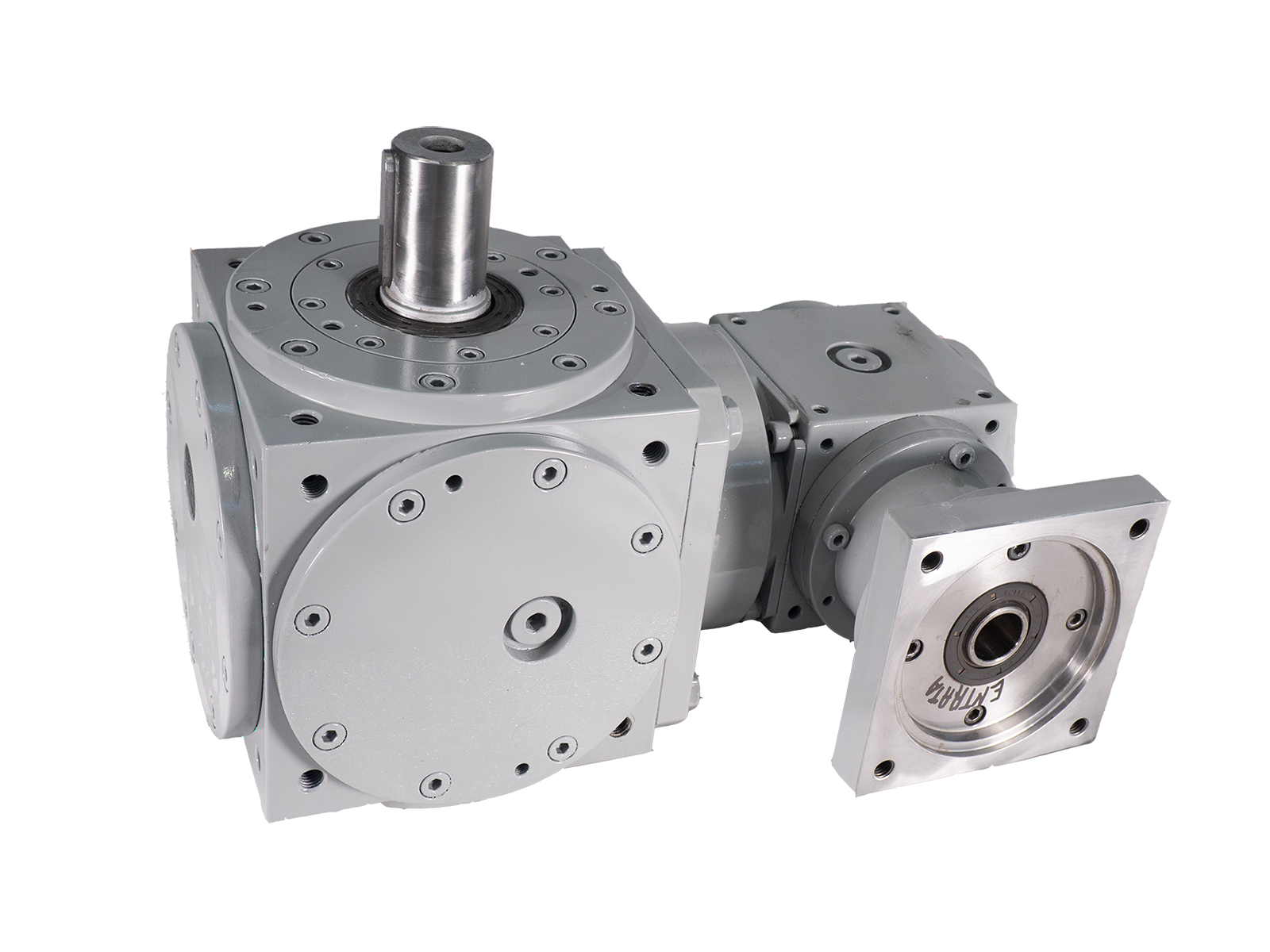

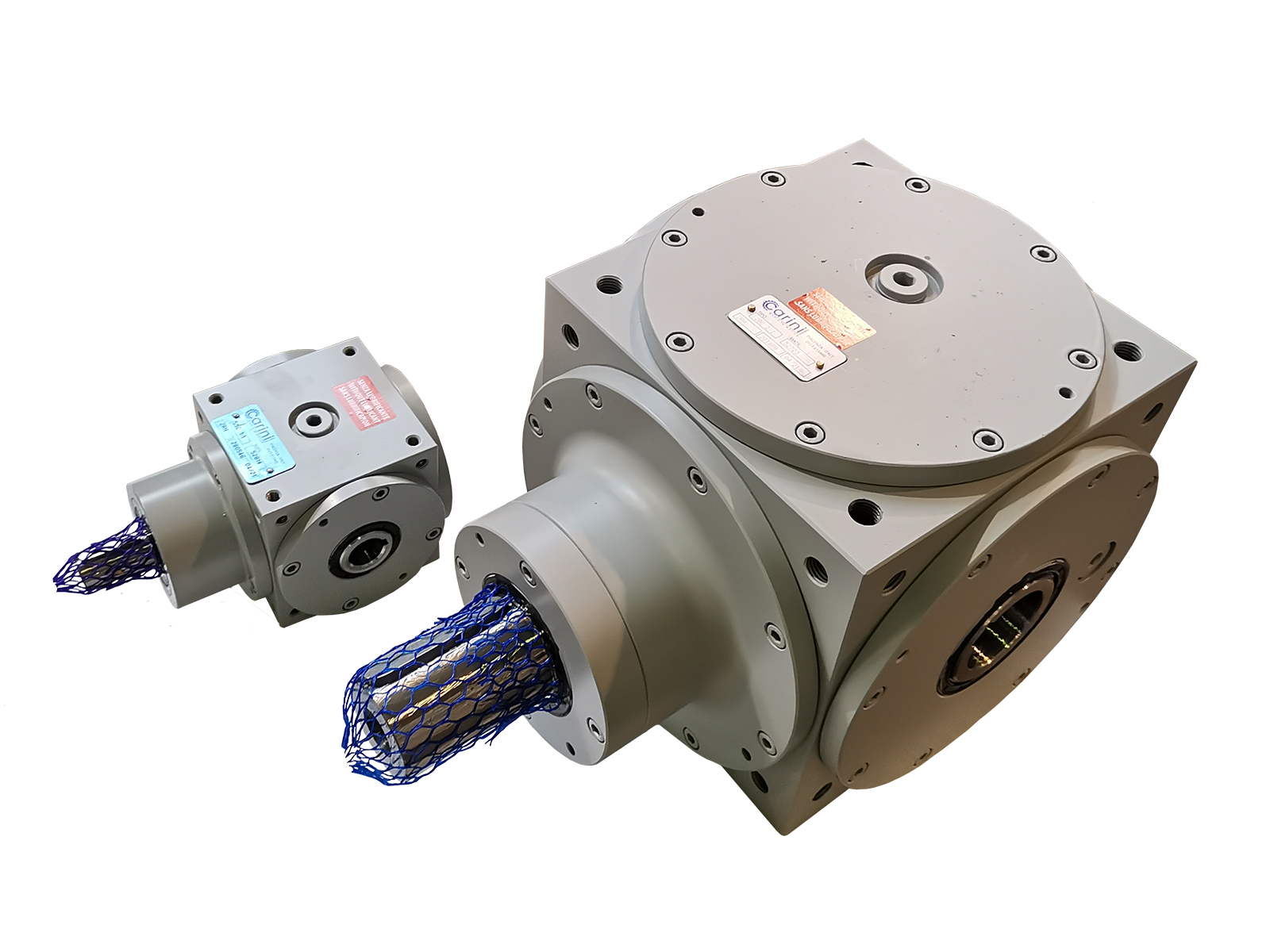

Standard Bevel Gear Boxes

our standard bevel gearbox is based only on our helical bevel gears. Its catalogue covers a wide range of dimensions , reduction ratios and...

Details

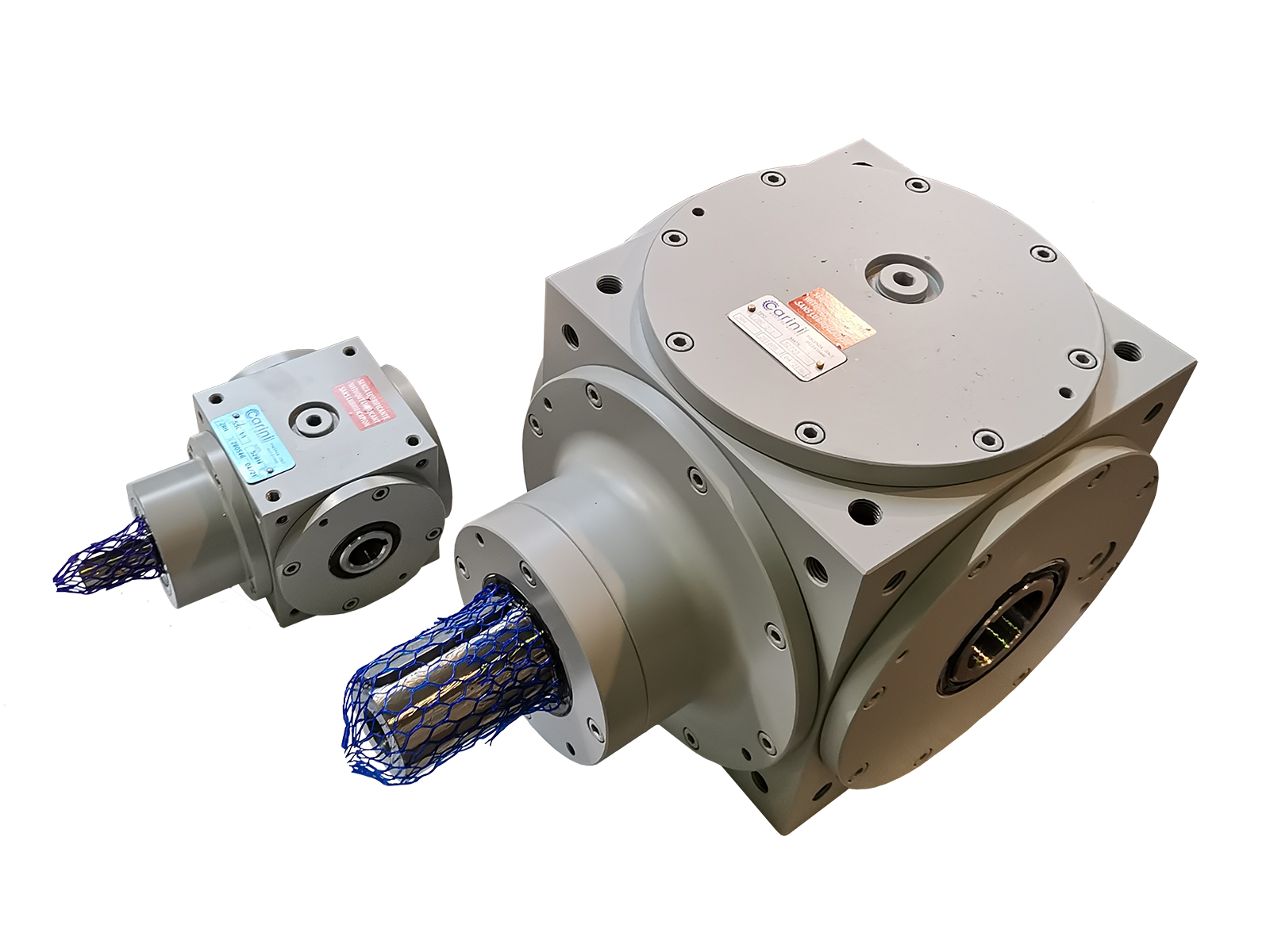

Special Bevel Gear Boxes

special bevel gearboxes are generally referred to customer problem solving, passing through engineering and/or complete re-design.

Details

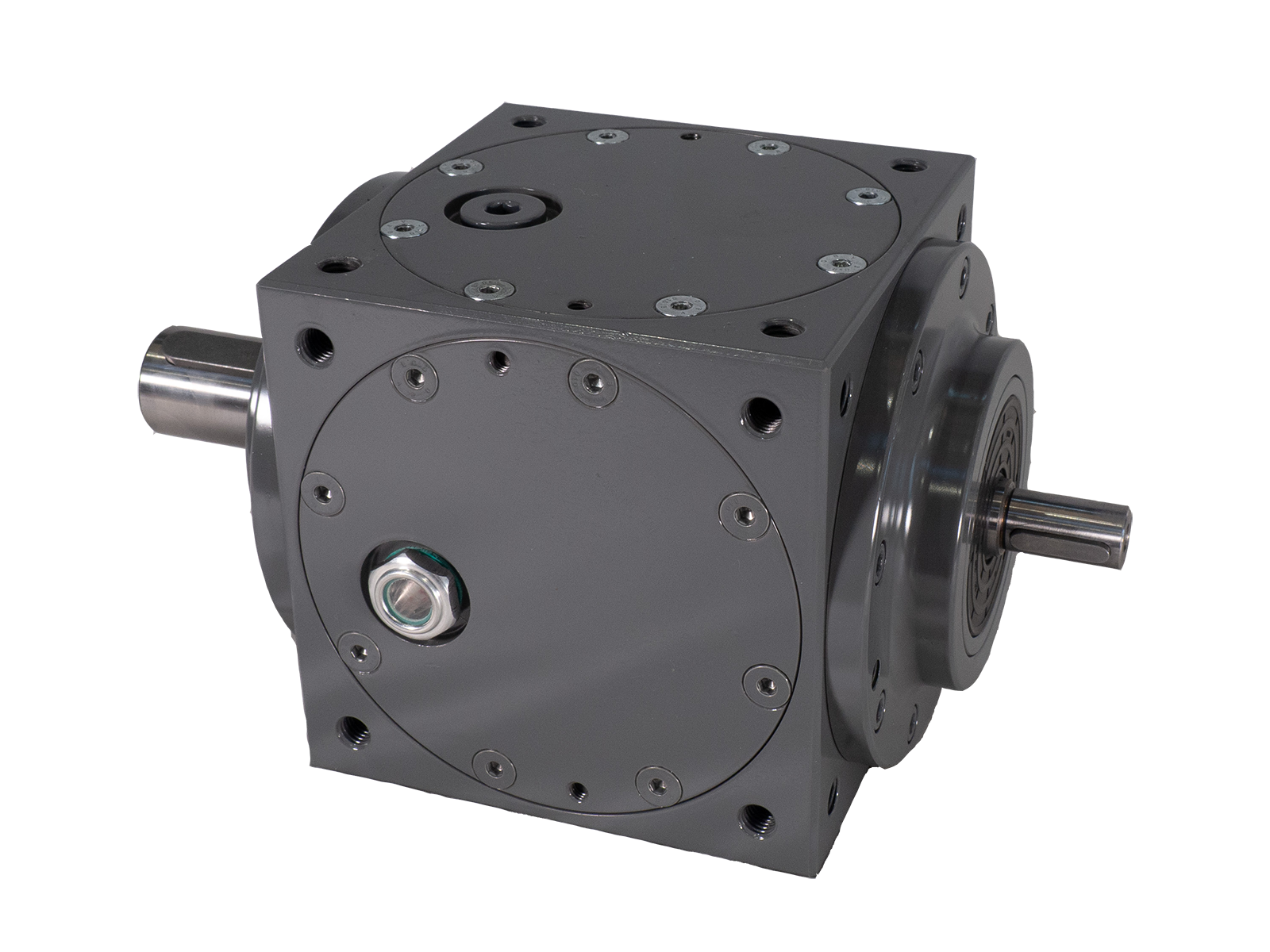

Customized Gear Boxes

customized bevel gearbox refers to our standard size and type one, but with modification that can be referred to materials (f.e. helical bevel gears,...

Details

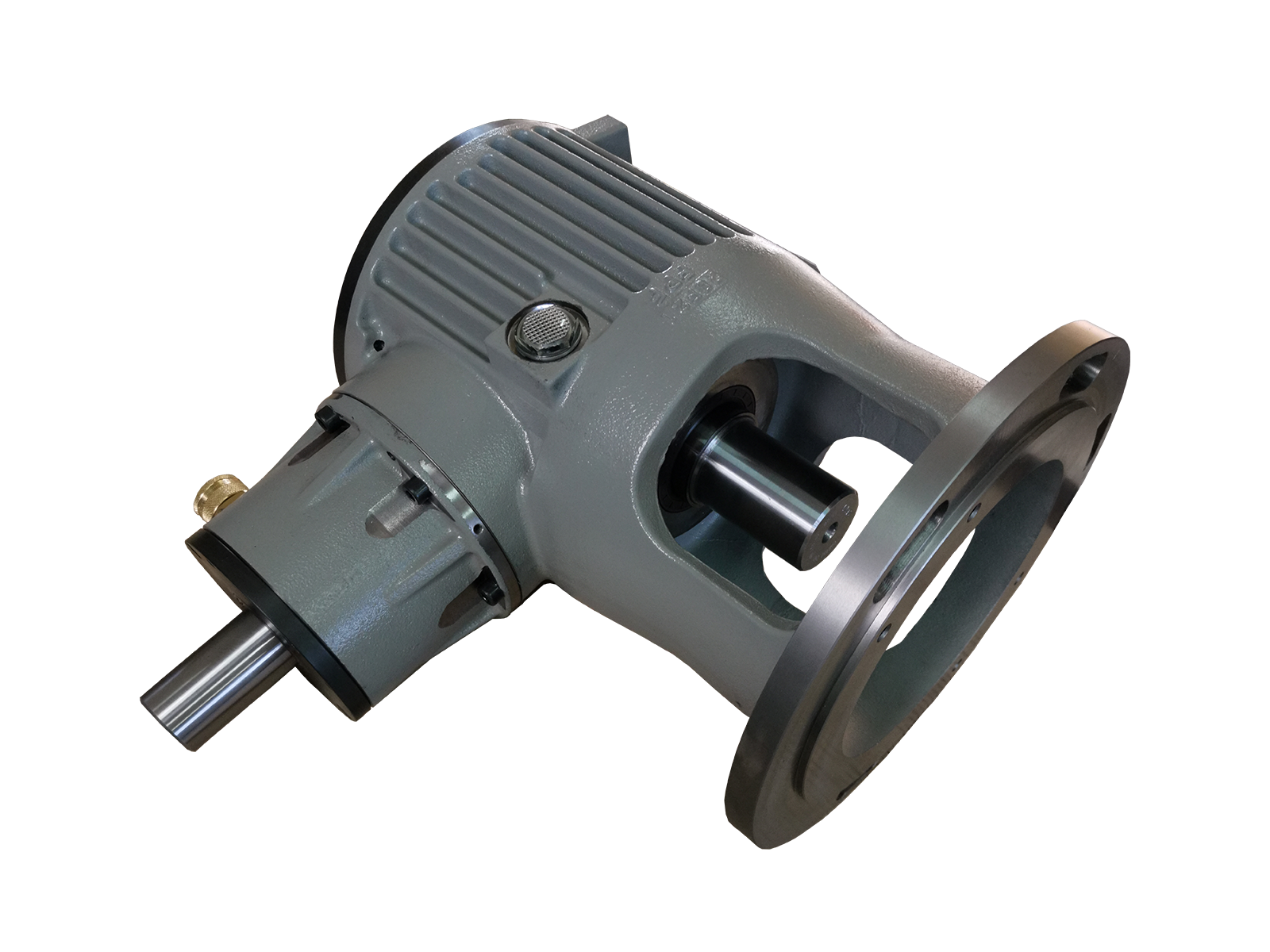

Third Part Project Angular Gearboxes

Third part design bevel gearbox are born directly from customer needs, and their designs. In some cases, co-engineered with our know-how.

Details

EXPLORE

Our Products

Standard Bevel Gear Boxes

our standard bevel gearbox is based only on our helical bevel gears. Its catalogue covers a wide range of dimensions , reduction ratios and transmissible power, declined in 12 construction types that satisfy a wide range of needs. More than this we can meet customer needs with different types of gearboxes: customized, special or third part designed gearboxes.

Details

Special Bevel Gear Boxes

special bevel gearboxes are generally referred to customer problem solving, passing through engineering and/or complete re-design.

Details

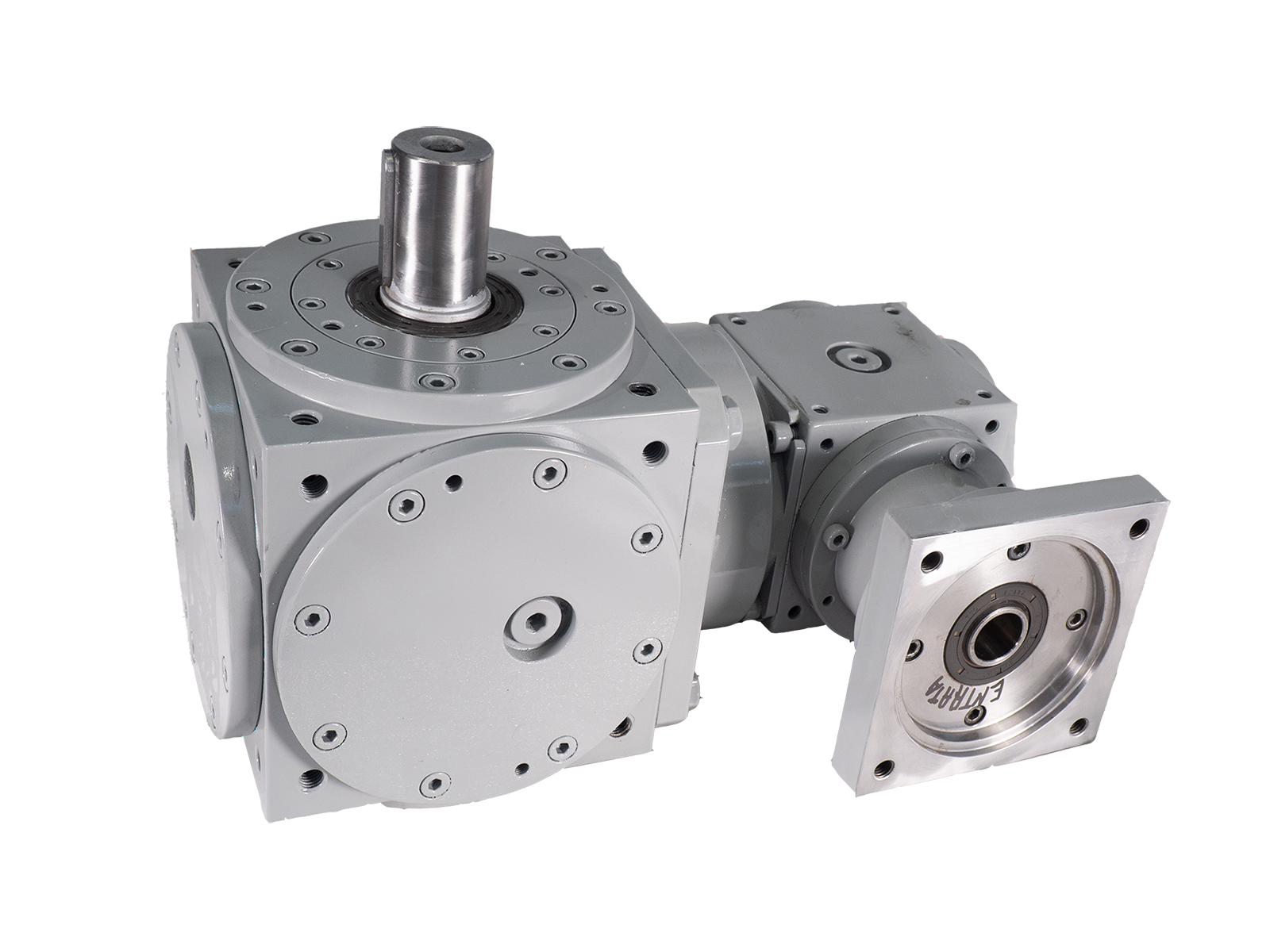

Customized Gear Boxes

customized bevel gearbox refers to our standard size and type one, but with modification that can be referred to materials (f.e. helical bevel gears, r.r.) and/or shaft type, and/or commercial items.

Details

Third Part Project Angular Gearboxes

Third part design bevel gearbox are born directly from customer needs, and their designs. In some cases, co-engineered with our know-how.

Details

Worms and Bronze Wheels

we produce worm and crown groups, with fixed or variable pitch, with the possibility of backlash recovery, mainly for applications with extremely accurate couplings or minimized backlash.

Details

Spiral/helical Bevel Gears

flagship of our gearboxes, always produced internally in our plant. Our know-how is available for third part projects, both in Gleason or Klingelnberg. Main and fundamental key-point of our production is the single-flank tester certifiability.

Details

Straight Bevel Gears

for less demanding applications than where bevel gears helical ones are used, but of course always internally produced. Our internal know-how can be available even for third part design, and co-engineered.

Details

Spur and Helical Gears

cylindrical gears, straight or helical teeth, is a necessary complement to realize more complex cinematics in power transmission. We manage rectified products only with high precision level (min. cat. 6), mainly used in critical conditions.

Details

Further Mechanical Components

gears, toothed shafts or complete cinematics are only some examples of our special production, not related to bevel gears or gearboxes. Full made in Carini…because of we have internally all the necessary resources to do them (in terms of people or machines).

Details

Warning: Attempt to read property "name" on bool in /web/htdocs/www.cariniindustria.it/home/en/wp-content/themes/industris/inc/backend/elementor-widgets/portfolio-filter.php on line 595

Warning: Attempt to read property "slug" on bool in /web/htdocs/www.cariniindustria.it/home/en/wp-content/themes/industris/inc/backend/elementor-widgets/portfolio-filter.php on line 596

Warning: Attempt to read property "name" on bool in /web/htdocs/www.cariniindustria.it/home/en/wp-content/themes/industris/inc/backend/elementor-widgets/portfolio-filter.php on line 595

Warning: Attempt to read property "slug" on bool in /web/htdocs/www.cariniindustria.it/home/en/wp-content/themes/industris/inc/backend/elementor-widgets/portfolio-filter.php on line 596

Warning: Attempt to read property "name" on bool in /web/htdocs/www.cariniindustria.it/home/en/wp-content/themes/industris/inc/backend/elementor-widgets/portfolio-filter.php on line 595

Warning: Attempt to read property "slug" on bool in /web/htdocs/www.cariniindustria.it/home/en/wp-content/themes/industris/inc/backend/elementor-widgets/portfolio-filter.php on line 596

Warning: Attempt to read property "name" on bool in /web/htdocs/www.cariniindustria.it/home/en/wp-content/themes/industris/inc/backend/elementor-widgets/portfolio-filter.php on line 595

Warning: Attempt to read property "slug" on bool in /web/htdocs/www.cariniindustria.it/home/en/wp-content/themes/industris/inc/backend/elementor-widgets/portfolio-filter.php on line 596

Warning: Attempt to read property "name" on bool in /web/htdocs/www.cariniindustria.it/home/en/wp-content/themes/industris/inc/backend/elementor-widgets/portfolio-filter.php on line 595

Warning: Attempt to read property "slug" on bool in /web/htdocs/www.cariniindustria.it/home/en/wp-content/themes/industris/inc/backend/elementor-widgets/portfolio-filter.php on line 596