You can’t judge a gearbox from its cover/case

In Carini Industria, Quality reflects Values and Principles we constantly refer to, together with Industry 4.0 concept, in the information, measures and results exchange between people and machines.

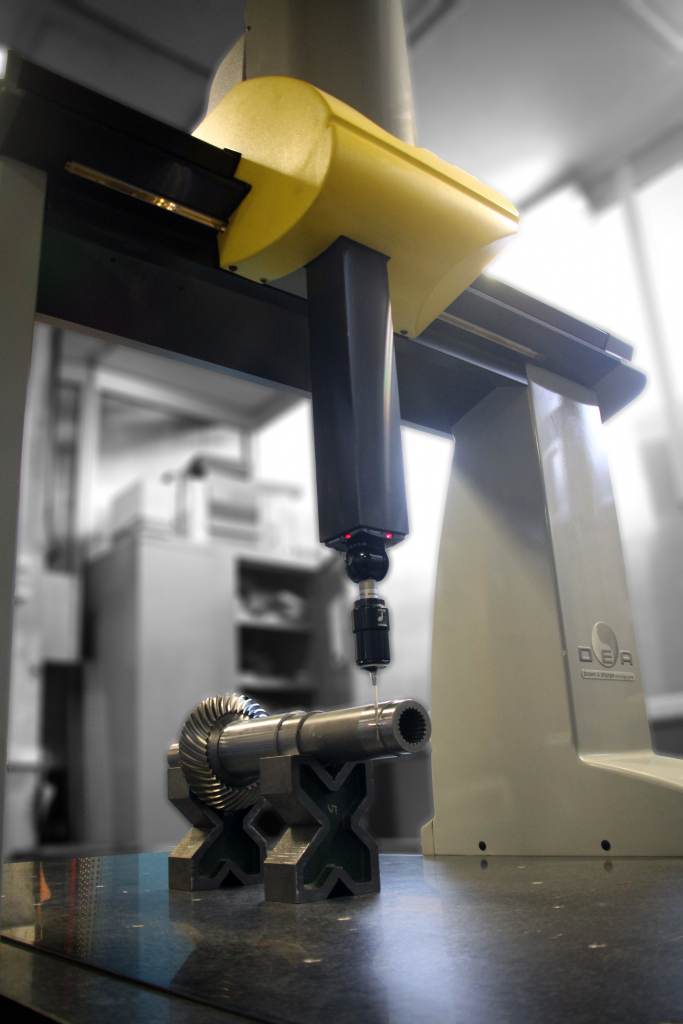

For this reason we placed the metrology dept in the middle of our plant, not only physically, but also ideally, being the core of our production system.

Besides raw materials and commercial components (e.g. SKF, FAG or Timken bearings) which are outsourced, the entire productive process is internal in our factory, resulting in a complete supply chain that reaches the highest quality levels… FULL MADE IN CARINI.

This process allows us to be flexible, designing and producing what our team is able to do and our machines can work…always improving, never stop learning.

Thanks to this model, we can check and internally certify our top-quality products, bevel gears (Klingelberg® or Gleason®) through our single-flank tester.

Worm screw and wheel check

So, applications that require durable and reliable items find in Carini Industria not only a supplier but complete an actual industrial partner.